The top reasons for catering maintenance call-outs

They are nearly all avoidable. Find out how...

1.Scale damage to Combination Oven steam tank

Scale is the No 1 threat to any appliance which has water as a crucial function component, paricularly in hard water areas.

At first it just shows as an unsightly chalk like deposit, however internally it

systematically builds on any surface. Appliances may seem functional but eventually will become

slow to respond, inefficient, unreliable and eventaully leading to catastrophic failure, and inevitable high cost repairs.

Solution: Understand local water conditions, instruct regular PPM and Inspection, use only

manufacturer cleaning tablets, install water softening if advised and react immediately to any digital display message.

Here is an example of limescale in a combination oven steam tank. The tank is totally choked with hardened scale. Unfortunately the repair was costly and came as a surprise as it believed to have been part of a daily cleaning routine.

2. Poor aeration / burner jet blockage

A clear and common sign of poor maintenance resulting in a dangerous cocktail of incomplete

combustion, black carbon residue, inefficient flame, and poor performance.

The cause can be anything from debris / ingress blockage, constricted gas flow, undersized pipework to damage within the burner or gas valve.

Immediate action is required:

You should Isolate immediately and seek the assistance of a qualified COMCAT engineer. This flame type posses an immediate Risk of Carbon Monoxide poisoning.

3. Dirty oil in fryers

Deep fat fryers with unmanaged dirty oil full of debris and carbon particles, will become difficult to heat and the flash point may rise or lower. Food will be tainted and fumes will become intrusive, ingress will become

hard to remove and eventually the burners struggle resulting in overall poor performance and effieciency.

Easy to resolve by PPM, and pro active oil management

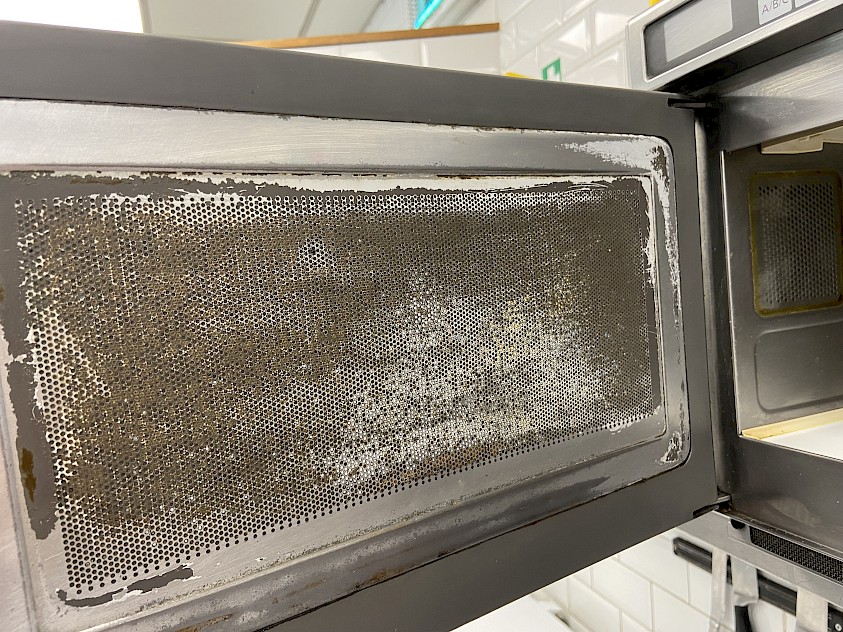

4. Over zealous cleaning

Of all the common microwave issues, this is the one that is likely to be harmful, ironically born of over cleaning. The emission protective screen has been removed by abrasive cleaning, cleaning should be by non-abrasive fabric, non-chemical cleaning agent ie lemon and water, wiped over and dried off with a paper cloth.

More kitchen nightmares to follow

Get in Contact Now

Our team is here to support you with all your repair, maintenance, and

installation needs.

Available

Monday-Friday, 8:30 AM to

5:00 PM, with 24/7 emergency service.